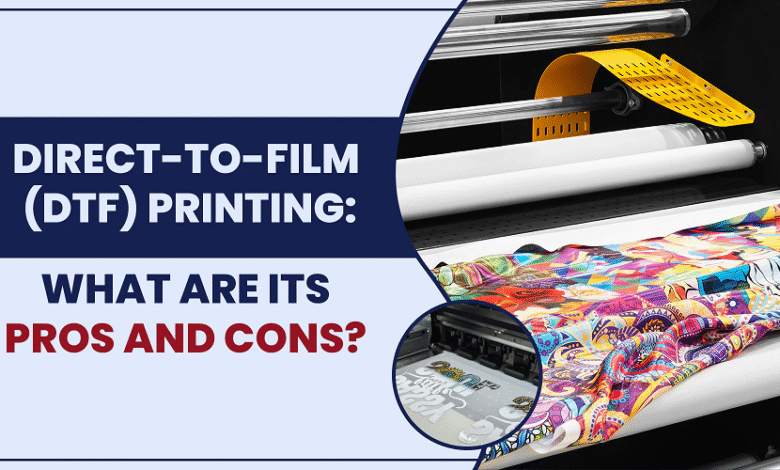

A Beginner’s Guide to Direct-to-Film Printing: Everything You Need to Know

Direct-to-Film (DTF) printing is making waves in the custom printing industry, and for good reason. This cutting-edge printing method is rapidly gaining popularity among businesses, from small print shops to larger custom apparel companies. Whether you’re looking to create personalized t-shirts or custom merchandise, DTF printing offers a high-quality, cost-effective solution that rivals traditional methods like screen printing and direct-to-garment (DTG) printing.

But what exactly is DTF printing? And how can you get started if you’re a beginner? In this guide, we’ll explore everything you need to know about DTF printing—its process, benefits, and how it stands out from other printing techniques.

What is Direct-to-Film Printing?

Direct-to-Film printing involves printing a design onto a special film, which is then transferred onto a garment or other surface. Unlike traditional screen printing, which requires stencils and multiple layers of ink, DTF printing uses a digital printer to transfer the design directly onto the film. This method offers vibrant, full-color prints with crisp details, making it ideal for custom designs and small batches.

DTF printing can be done on various materials, including cotton, polyester, and even mixed fabrics, making it a versatile choice for printing on apparel, accessories, and promotional products.

The DTF Printing Process: Step-by-Step

DTF printing involves a straightforward process that’s easy to understand, even for beginners. Here’s how it works:

Step 1: Design Creation

The first step in the DTF printing process is creating your design. You’ll need to use graphic design software like Adobe Illustrator or CorelDRAW to create or modify your artwork. Once you have your design ready, it’s important to save it in a format compatible with your printer. The design should be high-resolution to ensure crisp, detailed prints.

Step 2: Printing on Film

Next, you’ll print the design onto a special film. Here’s where a printer like the Epson Surecolor G6070 printer comes into play. This printer is a popular choice for DTF printing because it provides high-quality prints with vibrant color reproduction. The printer uses pigment-based ink, ensuring that the design will be long-lasting and resistant to fading. The design is printed in reverse, meaning it’s mirrored on the film to ensure proper transfer to the fabric.

Step 3: Powdering and Curing

After printing the design, you’ll need to apply an adhesive powder to the printed film. The powder sticks to the ink and helps bond the design to the fabric. This step is crucial for ensuring that the print stays in place once transferred.

Once the powder is applied, it’s time for curing. Curing involves heating the film in a special oven or heat press to melt the powder, creating a solid bond. This step is essential for durability, as it ensures the print will remain intact after multiple washes.

Step 4: Transfer to Garment

The final step is transferring the design from the film to the garment. Using a heat press, you’ll press the film onto the fabric at a specific temperature and pressure for a set amount of time. Once cooled, the film is peeled away, leaving behind a vibrant, durable design on the garment.

Advantages of DTF Printing

DTF printing offers numerous advantages over other printing methods. Here are a few reasons why it’s becoming a go-to choice for many print businesses:

High Quality and Detail

One of the main reasons DTF printing has become so popular is the exceptional print quality. The design produced is crisp, vibrant, and highly detailed. Whether you’re printing intricate logos, gradients, or photographs, DTF printing provides exceptional clarity and sharpness, often outperforming traditional methods like screen printing, which can sometimes struggle with fine details.

Cost-Effective for Small Runs

Unlike screen printing, which often requires a large initial setup cost, DTF printing is more cost-effective for smaller runs. There’s no need for expensive screens or setup time for each color. This makes it an ideal solution for businesses looking to print custom designs in smaller quantities or for personalized merchandise.

No Need for Pre-Treatment

Another benefit of DTF printing is that it doesn’t require pre-treatment of the garment, which is often necessary for other methods like DTG. This not only saves time but also reduces the complexity of the process. You can print directly onto a variety of fabrics without worrying about additional steps.

Versatility

DTF printing is incredibly versatile, making it suitable for a wide range of materials. You can print on cotton, polyester, blends, and even non-fabric items like tote bags and promotional products. This makes it an excellent choice for businesses that want to offer custom prints across a variety of products.

DTF vs. Other Printing Methods

If you’re familiar with other printing techniques, you might be wondering how DTF printing compares to other popular methods. Here’s a quick breakdown:

DTF vs. DTG (Direct-to-Garment)

DTG printing is similar to DTF in that it uses a digital printer to print designs directly onto fabric. However, DTG requires the garment to be pre-treated with a special solution to ensure ink adhesion. This makes DTF more efficient and less time-consuming, especially for smaller runs.

DTF vs. Screen Printing

Screen printing is a traditional method where ink is applied through a stencil onto the fabric. While it’s ideal for large runs of the same design, screen printing isn’t as versatile as DTF. DTF can print full-color designs and is better suited for small to medium-sized orders, while screen printing works best for simple, large designs.

DTF vs. Heat Transfer

Heat transfer printing involves printing a design onto transfer paper, which is then applied to the fabric using heat. While it’s similar to DTF in the transfer process, DTF prints directly onto the film, offering more durability and less risk of the design peeling or cracking over time.

Common Challenges and How to Overcome Them

While DTF printing offers many benefits, there are a few challenges that beginners should be aware of:

Adhesive Powder Issues

Getting the right amount of adhesive powder can be tricky. Too much powder can create a thick, heavy print, while too little can result in a design that fades or cracks. The key is to find the right balance and practice to perfect the application process.

Curing Process

Curing the film properly is essential for ensuring the durability of the design. Make sure to follow the recommended curing time and temperature guidelines to avoid under-curing or over-curing, which can affect the final result.

Getting Started with DTF Printing

If you’re ready to start with DTF printing, here’s what you’ll need:

- Printer: An Epson Surecolor G6070 printer or other compatible DTF printer.

- Heat Press: A heat press machine to transfer the design onto the garment.

- Film and Adhesive Powder: Special transfer film and adhesive powder for the printing process.

- Design Software: Programs like Adobe Illustrator or CorelDRAW to create your designs.

Conclusion

Direct-to-Film printing offers an exciting opportunity for businesses looking to produce high-quality, cost-effective custom prints. With its vibrant colors, detail-rich designs, and versatility, it’s quickly becoming the preferred choice for many. Whether you’re printing t-shirts, tote bags, or other promotional items, DTF printing provides a modern solution for today’s custom printing needs. So, if you’re ready to get started, explore the world of DTF printing and unlock its potential for your business.